d

Production

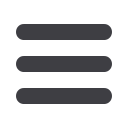

FLEXIBLE AND FULLY AUTO-

MATED MOULDING PROCESS

The raw materials are transferred from

the storage tank facility to the mixing

tank through a closed computer-control-

led system. This ensures uniform quality

and maximum usage of the raw materi-

als. The mixing systems have consider-

able flexibility, making it possible to meet

most quality requirements as regards ma-

terial mixtures. The filling of the moulds

is also automated. This takes place in

different production lines and makes an

efficient and flexible production.

The production itself takes place in closed

systems without use of ozone-destructive

CFC gases. When the chemical reaction

is completed, the product is 100% stable

and it does not give off any pollution

through waste gases or harmful toxins.

With our three production plants and a

total of six production lines, Sandella is

the largest independent player within the

European market for furniture.

Quality/Comfort

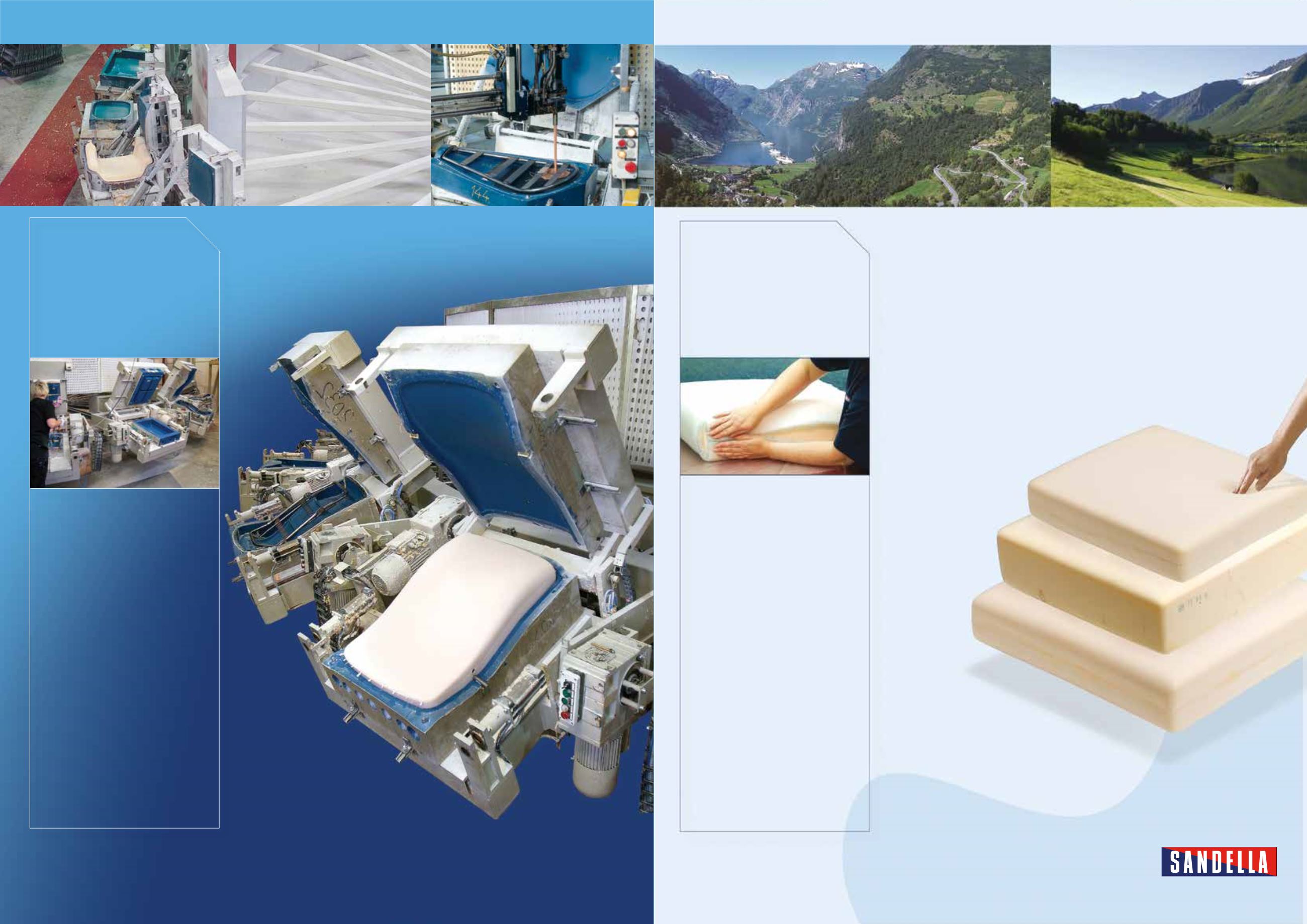

The high degree of elasticity and the

good side support provide the maximum

correct sitting comfort no matter where

you sit in the furniture. The moulded cold

cure foam’s unmatched qualities also

provide the correct sitting depth for all

requirements. Moulding also has the

advantage that it is possible to adjust the

softness and elasticity completely to the

requirements of each individual product.

Moulded cushions are particularly du-

rable and maintain their original shape

and quality even after several years’ use.

Moulded cold cure foam (polyurethane

foam) has considerably improved and

consistent qualities compared to the

inconsistencies of slab stock foam. This

is true for both the compression set

and sag factor, which describe the

foam’s ability to take pressure without

collapsing.

THE UNMATCHED QUALITIES OF

MOULDED COLD CURE FOAM

PROVIDE CUSTOMER-FRIENDLY

SITTING COMFORT